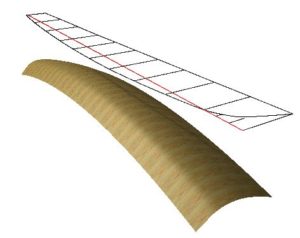

One fabricated, a reference line and offsets are used to mark the cut lines on each panel to make the hull halves. Again the computer generated image illustrates the concept.

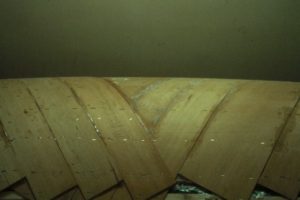

The cold molding process involves stapling a series of veneer strips to the mold in 3 layers glued with marine epoxy. Each veneer strip must be marked and trimmed to mate with its neighbor.

The completed panel is removed from the mold (with great effort) and a the hull half is cut to shape.